While a flushing toilet is (thankfully) nothing new, there are modern advancements that are changing the way toilets use water to conserve natural resources. Today’s flush toilets work a bit differently from the devices of a few decades ago, and new technological bells and whistles continue to crop up.

Today, there is a wider range of toilet models available for consumers, both for residential and commercial properties. Whereas gravity flush toilets used to be the norm, consumers can now opt for all kinds of flushing mechanisms, such as high tank, low-flush, and smart toilets. While the result is the same—you get an adequate flush to remove waste and clean the bowl—the process varies depending on the model.

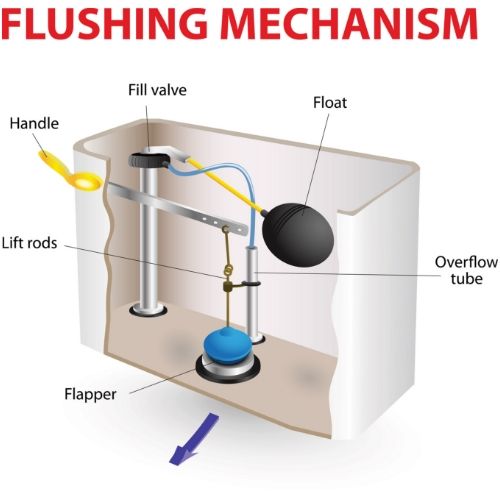

The Tank Mechanisms

In the center of the tank at the bottom is a large hole that leads to the rim of the toilet bowl with a stopper that plugs the hole and prevents the water from flowing into the bowl. The stopper is attached to a chain that in turn is connected to the handle of the tank. When the handle is turned or pushed, it lifts the stopper out of the hole and allows the water stored in the tank to quickly run into the rim of the bowl. As the water level in the tank flows out, the float control on the refill valve drops and turns the water on to refill the tank.

Moving Away From the Outdated Gravity Flush Toilet

To provide some perspective, the gravity flush toilet worked by having the tank mounted to the wall above the toilet bowl. A chain allows a person to flush the toilet by pulling the chain to release water from the tank to the bowl. Since the tank was situated above the bowl, it relied partly on gravity to force water into the bowl to remove waste.

Over time, manufacturers improved the flushing system so that the tank could sit on the toilet bowl instead. Some homeowners may opt for the high tank toilet purely for aesthetics, but most people immediately recognize the low tank toilet, as it has been a mainstay in homes for years.

So, what’s the problem? As toilet technology has progressed, there are more low-flow designs on the market. Also called high-efficiency toilets, these models cut down on the amount of water used in a flush, helping to conserve water and have a smaller impact on the environment. The trade off is that low-flow toilets require greater pressure, something that a gravity flush toilet can’t provide.

More Pressure, Less Water

These new toilets typically need around 20 to 25 psi of pressure, at a minimum, to produce an adequate flush. Therefore, newer flush toilets needed to have a slightly different flushing mechanism to provide for these pressure changes.

In these toilets, one will find a decent-sized opening at the bottom-center of the water tank. This opening descends into a long tunnel that leads to the rim of the toilet bowl. Also within the water tank is a lever that is attached to the flusher, which sits on the outside of the tank. When someone pushes the flusher handle down, the lever inside the tank moves upwards.

Attached to the lever is one end of a thin chain, with the other end being attached to the stopper at the bottom of the tank. The stopper sits on top of the large opening that leads to the rim of the bowl. So, when someone flushes the toilet, the lever activates the chain, which yanks the stopper up, revealing the large opening and allowing water to flow into it.

The force of the stopper lifting off of the opening causes a rush of water from the tank to go into the toilet bowl, and this is what helps to clear away waste and residue. While the water from the tank is rushing into the bowl, the tank’s water level will go down. For this reason, it has another mechanism inside, a toilet float.

The float monitors the water level in the tank, and when it gets low, the float activates the refill valve to let more water into the tank. This water comes from the main plumbing line in the bathroom. As the tank refills with water, the stopper falls back onto the large opening at the bottom to stop water from flowing out.

There are a couple of ways that can work. Either the stopper or the float is attached to the chain that’s connected to the flusher lever, and this is what causes the stopper to fall back into place once the water in the tank reaches a sufficient level. Once the water (and thus, the float) reaches a predetermined level in the tank, the refill valve will shut off and stop pouring out water. This will also cause the refilling sound that occurs after a flush to stop.

Getting Rid of the Waste Water

Finally, the DWV (Drain-Waste-Vent) System will carry the wastewater out of the building. The DWV system is hooked up to the pipes behind the wall. As the name suggests, it drains the waste away and provides a vent for sewage and waste gases to escape into the air. Typically, the vent pipes sit on the roof of the building, and while gases escape, atmospheric pressure gets sucked into the vent pipe and prevents those gases from seeping into the bathroom.

Years ago, there was the threat of gases leaking into the bathroom and accumulating within the drainage system. Today, that’s no longer a concern, nor is the excessive use of water.